Tier II Supplier Taskforce Support

The Challenge

In September 2020, a Tier II supplier created a staffing glidepath at 350 personnel targeting full employment at 495+ . With the significant lack of

resources, repeat quality issues, 2-5 expedited trucks including 6 truck milk runs daily, production was struggling to keep up with demand. AMBE

resources were brought in to help stabilize the production, logistics and quality processes and improve the abilities to build a bank against the request of this Tier II supplier. AMBE biggest challenge was gaining the suppliers trust to become part of their process and help eliminate the risk to the OEM.

The Solution

AMBE resources performed observational plant and assembly walk throughs, while focusing on strategic audits in troubled areas. AMBE was able gained

the trust of the Tier II Supplier by demonstrating a viable improvement plan of current findings and open areas of opportunity such as:

• Blue Collar Staffing support (General Labor, Die Casting)

• Renovating and transforming a vacant area of the plant to a pre-final inspection area to filter out any quality issue parts before making it to final

inspection and finished goods.

• Creating work instructions for the pre-inspection and trained

• Developed a incentivized plan for teams that achieved 2 weeks without a quality issue to final inspection

• Improved die changeover from 1 day to 4 hours

• Improved Preventative Maintenance schedule by having the die get PM and turn around to back in machine from 3 – 5 days to 1.5 days

• Improved machine uptime by more than 15%

• Improved first time throughput by establishing at point quality checks at each step of the process

• Eliminated expedited trucks by improving production efficiency and machine uptime.

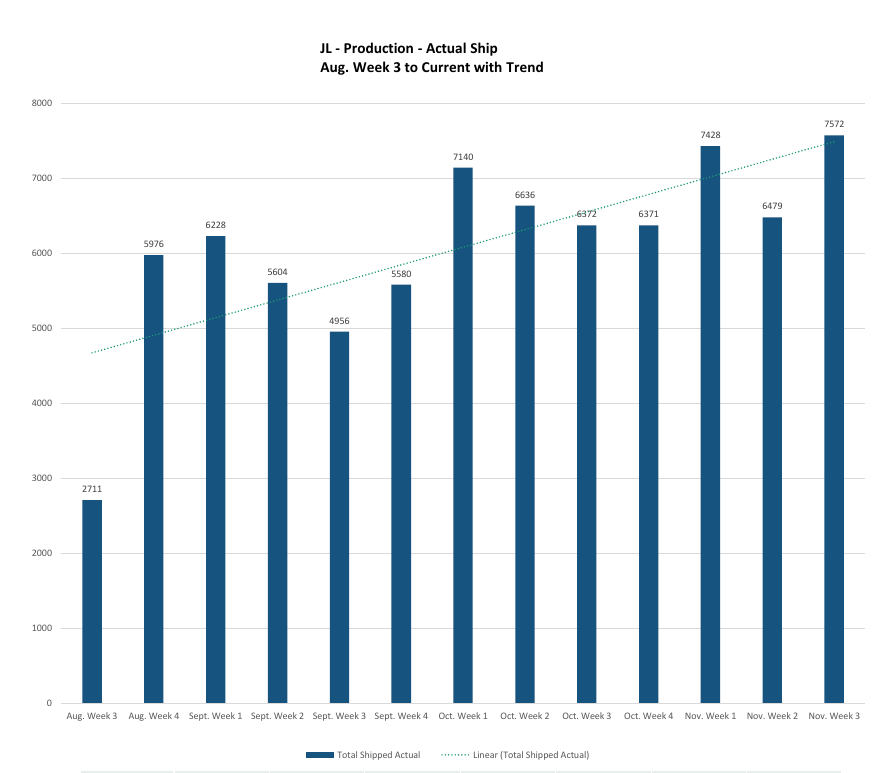

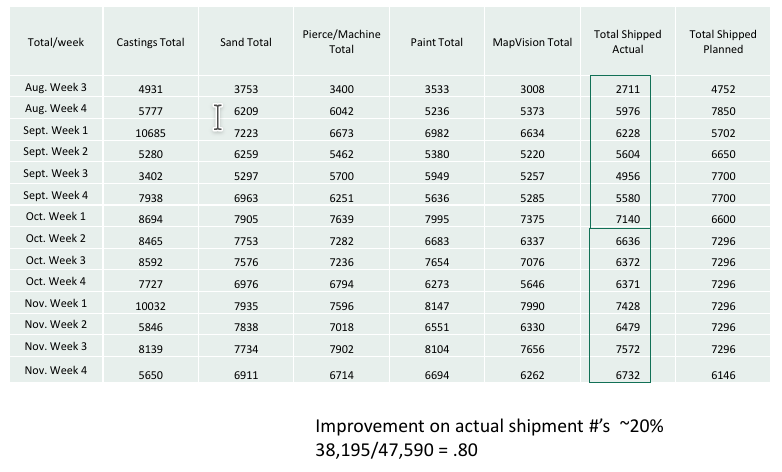

The Result

Staffing

Before

After

Major quality repeats

Before

After

Production efficiency and machine uptime

Before

After

Expedited shipments

Before

After