Noise Reduction Automotive Tier-1 Supplier

The Challenge

Company requested our support since they were having problems getting paid for overdue invoices, but at the same time were getting charged for

logistics issues, they assumed this was caused for ASN’s problems.

We have been supporting our client by providing support in the following activities:

I. Determinate Overdue Invoices root-cause: Analyze and getting evidence of each shipment and ASN transmission

II. Getting information of claims received: Looking with their customers for detailed information on charges received

III. ERP issues: Identify problems related with bad or poor parameters set up at system

IV. Improving shipping process: ASN’s transmission, Labelling and paperwork managed properly

V. Reducing Expedite Freights: Several charges received due to expedited freights to customers, that were not managed properly

VI. Recognizing other modes of failure: Not only ASN’s were causing problems, more than 50% of the issues were related to other logistics matters

AMBE helped to quickly identity and visualize the main issues, providing support by performing or coordinating the improvement of these.

The Solution

Determinate and keeping record of every logistics problem related with their customers that might cause a penalty or and overdue invoice

- Database generated with every logistic issue related with customers

- Measuring and analyzing each topic to take decisions on improvements

- Coordinating several changes on ERP (SAP) with IT area, based on Germany

- Analyzing Releases received by customers in order to avoid undershipments

- Implementing strategies to avoid quantity discrepancies on shipments

- Double verifications when shipping to catch mislabeling

- Integrate other company areas on improvement process as IT, Quality & Finance

- Helping to negotiating with OEM’s payment of overdue invoices

- Supporting on new projects launch to avoid having same logistics issues

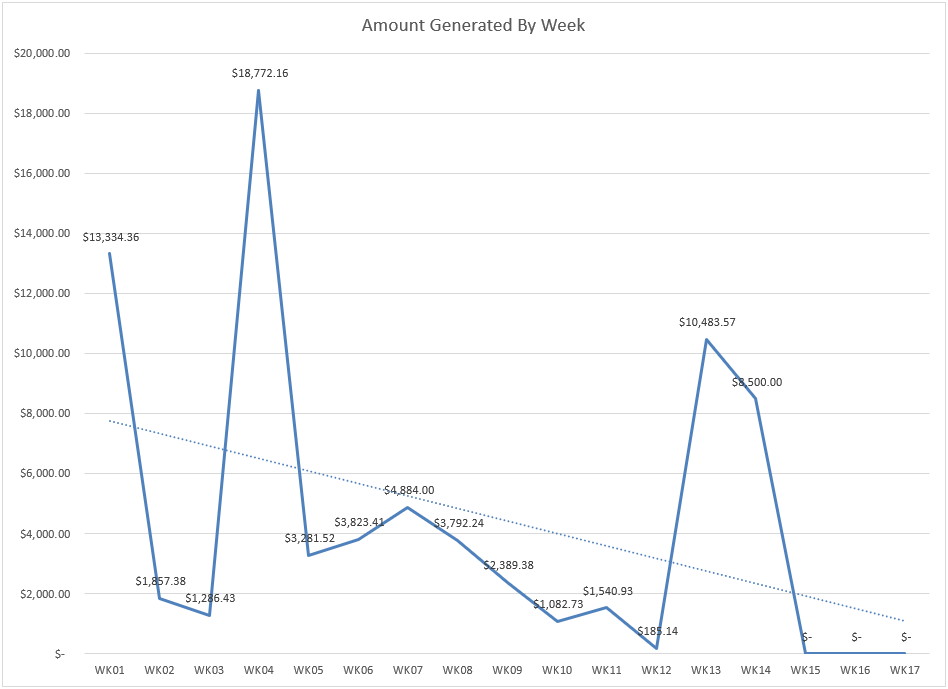

The Result

Communication

Before

After

Shipments information

Before

After

Internal Information Management

Before

After

Costs

Before

After