Operations ASC & Fans & Air Filtration Client

The Challenge

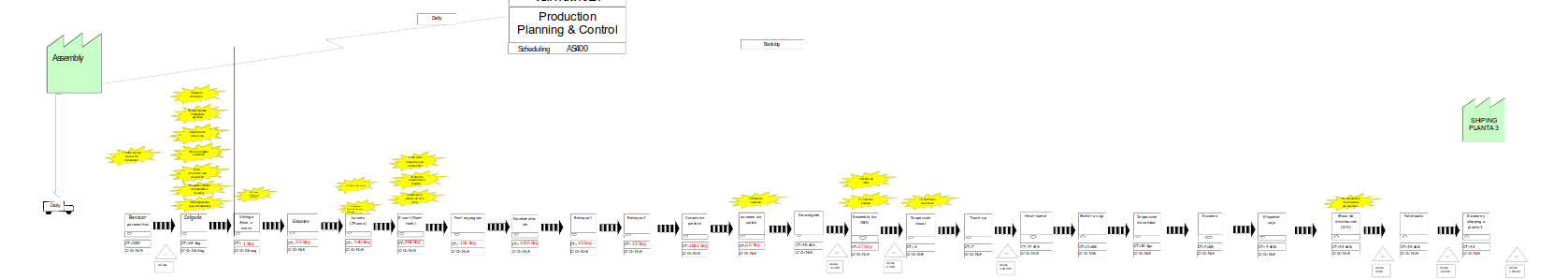

Customer requests a Value Stream Mapping Assessment (including Transactional) of to its two facilities in El Paso, TX & Ciudad Juárez Mexico

To help our client we worked with the supplier to improve and eliminate:

I. Management of flow of materials and information required to bring a product to customers in a timely manner.

• Current system (MacPack) needs to be changed by an electronic Management system (ERP)

• Customer concerns due to late delivery of Products

• Flow of information and Scheduling is critical in Plants.

II.Identification of bottle necks and opportunities for improvement

• Mass production in place

• Crisis Management

• Roles and responsibilities are unclear

• Lack of communication / analysis in Plant

• Waste is evident in Plants in terms of Quality & Delivery

III. AMBE Coaching to Customer Management team in the VSM process

• Teaching & learning process in the energy room

• Focus on priorities

The Solution

- Map process as a team with all floor experts

- Review KPIs performance to crosscheck opportunities

- Daily report Map development progress

- Weight all opportunities based on Impact, Frequency & Control

- Visualize and analyze the bottleneck Operations

- Based on the highest NPR develop an action matrix

- Identify the line with more opportunities or bottlenecks to work in as a pilot area

- Implement and check improvements

- Develop a plan to implement at all areas

- Assign Champions per area to support teams

- Daily check progress and adjust as needed