Headrest Automotive Customer

The Challenge

Root cause was the constant errors transmitting ASN’s to Tier 1 that caused inventory discrepancies that affect the flow of product to final BMW location

I. Demand / Requirement (Grammer-Magna) analysis to determine failure to maintain OH-FG inventories target on each location.

II. EDI CUM’s (Grammer-Magna) needs review & update

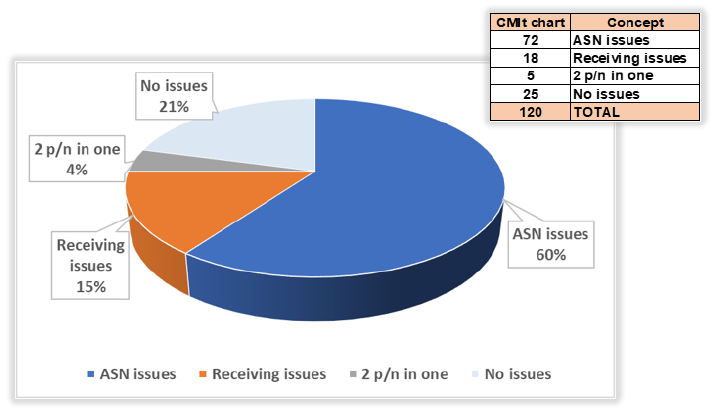

a) Initial screening of findings – 120 references

b) Complete rest of missing references: 37 Magna, 7 Grammer

III. Execute FG physical inventory counts as needed *Grammer

IV. Proper use of EDI platform instead of Excel files for daily hot-list follow up, to prevent new hot items to show up.

a) Sample proposal submitted (AMBE)

b) Magna/Grammer to develop strategy for EDI usage Open

V. Daily follow up on critical shipments as requested by Magna after results of daily meeting (charters, hand carriers, regular trucks)

Grammer not addressing CUM topics as Prio.1

• Root cause analysis not followed up by Grammer – No feedback provided either

• System differences not revised, nor updated

• Meetings: Late attendance and without accurate data

AMBE help to analyze complete EDI process to focus in the bigger offender causing inventory discrepancies with their Tier1 customer

The Solution

Gather all history data of errors, compare cumulative figures Tier2 vs. Tier1, adjust accordingly and start a clean process avoiding further errors.

I. Demand / requirements.

a) Attainment of EDI load twice a week

b) Immediate review of variations

II. Cum differences (Total analyzed 120 items)

a) Conclude adjustments

b) Maintain Open issue list and KPI

c) Start over / random audits

III. ASN’s failure / missing

a) Reinforce dock audits

b) End of day review.

c) Understand MSSC ASN receipt system

IV. Proper use of EDI platform instead of Excel files

a) Control of Cum variations

b) Confidence on EDI

c) Less use of manual reports

V. Demand variations

a) Agree on way of analysis

b) Reflect agreements on EDI

The Result

ASNtransmission errors

Before

After

System & Training

Before

After

Inventory Discrepancies

Before

After

Costs

Before

After