Interior-Cooling Automotive Supplier for OEM Client

The Challenge

Supplier was in a continuous backlog situation, while the OEM client was ramping up production of a new model car and had not yet reached maximum.

To help our client we worked with the supplier to improve and eliminate:

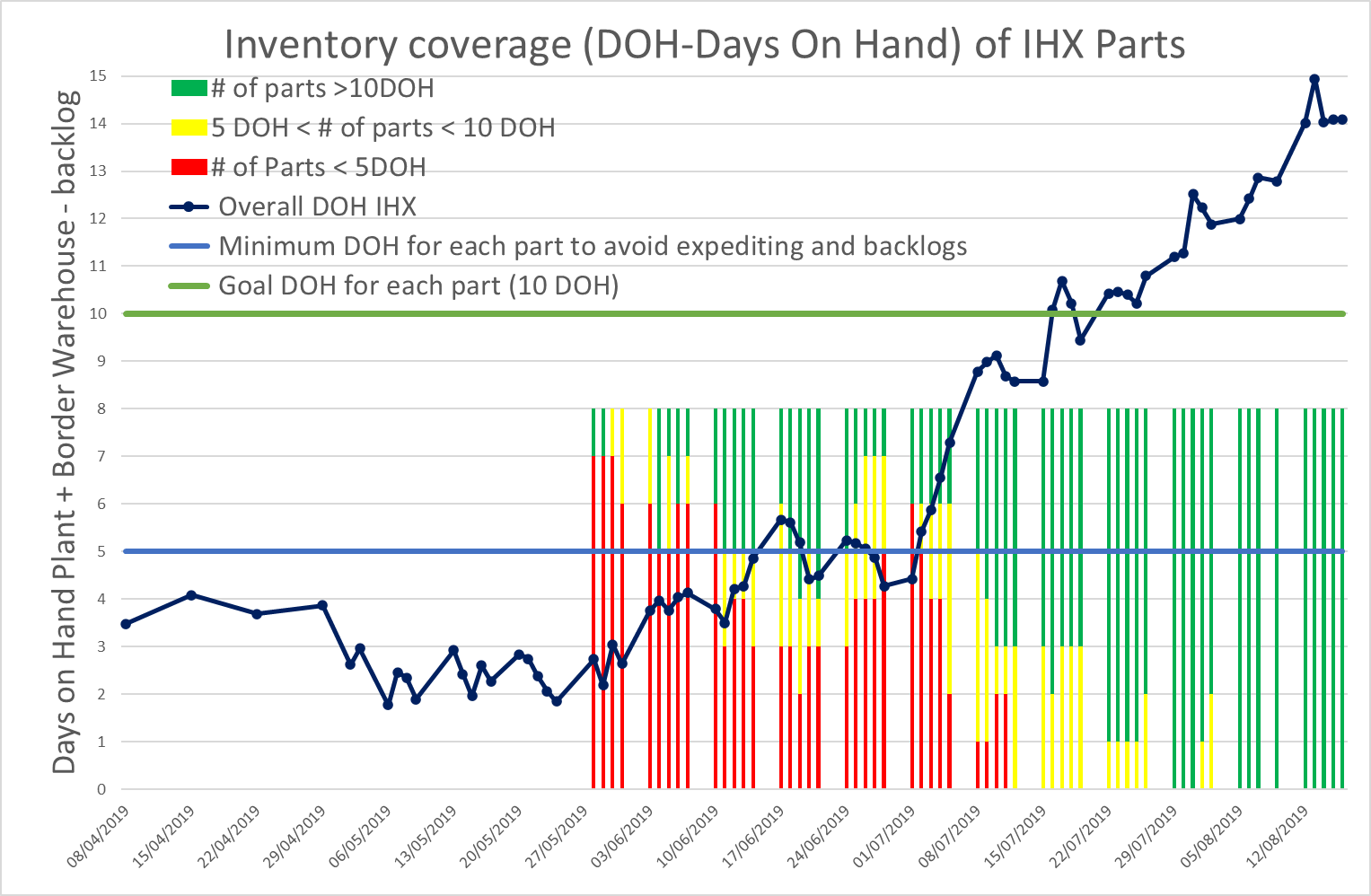

I. Back log parts: Continuously over 500 parts when project initiated and only 2 days coverage

II. Premium freight: Daily expedited trucks direct to OEM instead use of regular OEM JIT trucks

III. ASN issues: Bypassing regular quality, packing and shipping procedures caused deviations and SCAR reports

IV. Hampering communication on the daily production and shipments’ status as well as the root causes and planned action

V. Unclarity on the root cause: No clear information from the supplier on real capacity and staffing problems

VI. Fear of the OEM client that the ongoing crisis might affect the quality of the products

VII. Escalation by the OEM: Supplier was on the highest escalation step, involving need to inform the auditing body and a stop on new business

AMBE helped to quickly identity and visualize the main issues, bridge the communication gap and coach the supplier into improved performance.

The Solution

Map the actual processes on the factory floor, generate data to analyze performance, work with the people to understand and solve the issues.

- Daily AM and PM info to executive levels of both OEM and supplier

- Daily and weekly conference call cadence

- Take custody of supplier production and shipment reporting

- Visualize daily performance, issues and bottlenecks

- Separate performance and capacity issues and actions required

- Support supplier with weekly presentation of progress on action plan

- Catalyze OEM-Supplier cooperation to understand changing requirements and deviations on CUMs quantities

- Catalyze fast-track approval of OEM for use of additional equipment

- Solve ASN issues together with OEM and the supplier

- Analyze and improve supplier capacity planning and reporting

The Result

Communication

Before

After

Escalation

Before

After

Back log and shortage of components

Before

After

Costs

Before

After