Back

Inventory Accuracy Tier-1 Supplier

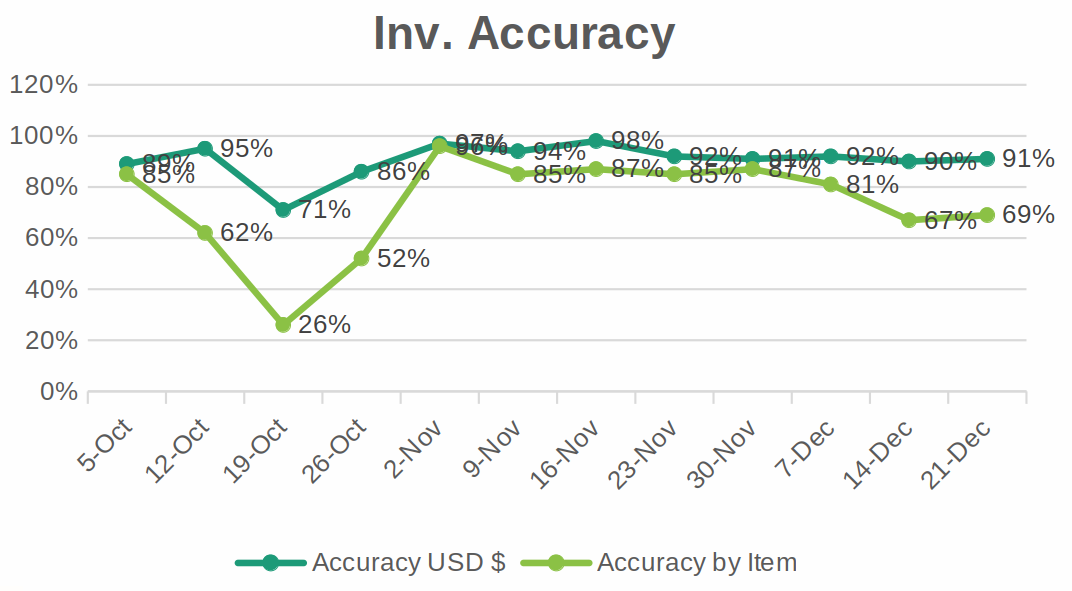

Our Client a Tier-1 Supplier who is dealing with very poor Inventory Control and as a result a 69% Inventory Accuracy was recorded in the Last Plant Inventory excersise

The Challenge

Company requested our support to identify which are the process and conditions that

caused this performance deterioration

These are our findings during our visit to their facilities and process review :

- Material every where at Receiving Area, Warehouse and Kitting operations

- There was no evidence of a process in place to follow or monitor physically Inventory

- Because of this, finding material is a difficult task, it is operator dependent

- All types of material at warehouse (current, obsolete, not in use, MRO)

- It is obvious excess material, but not obvious the gap for warehouse capacity

The Solution

Remove major offenders and roadblocks that directly affects Inventory Accuracy rate

- Re-negotiate Vendor Commercial Agreements related to Lead Time considerations

- Determine real warehouse capacity vs needed, find the gap

- Remove unnecessary material from warehouse

- Increase warehouse capacity as required

- Improve Material management (Distribution and Monitoring)

- Re-engineering Kitting operation

- Re-engineering Receiving area operation

- Determine the need for a Consolidation Center and the better location to be

- Establish clear responsibilities for it and KPIs to monitor

The Result

Communication

Before

Poor communication betwee Plant and Corporate Procurement Division where all decisión are made related to Vendor Comercial Agreements without consider the specific opertional requirements from Plant

After

Improve the communication between Plant and Corporate Procurement Division porviding specific financial nformation related to impact decisión making process to improve Plant Oeration performance

Internal Information Management

Before

All information is centralized by Plant Planning departament including KPI’s for the overall operation missing some critical ones belonging to the floor operations that can early alert for some future disruption

After

Implement and monitor KPIs for each of the departaments were the process and informatin is created: Shipping/Receiving Area, Warehouse, Cycle Counts, Production Control, Scheduling

Cost

Before

Material Inventory Level ($), Obsolescence Cost ($), Material Inventory Level ($), Obsolescence Cost ($), PRIVATE Transportation Cost & ($), Expedite Cost ($), Inventory Adjustments ($) , Scrap for Overhandling ($)

After

Material Inventory Level ($), Obsolescence Cost ($), Transportation Cost ($), Expedite Cost ($), Inventory Adjustments ($) , Scrap for Overhandling ($)