Material Flow Automotive Tier-1 Supplier

The Challenge

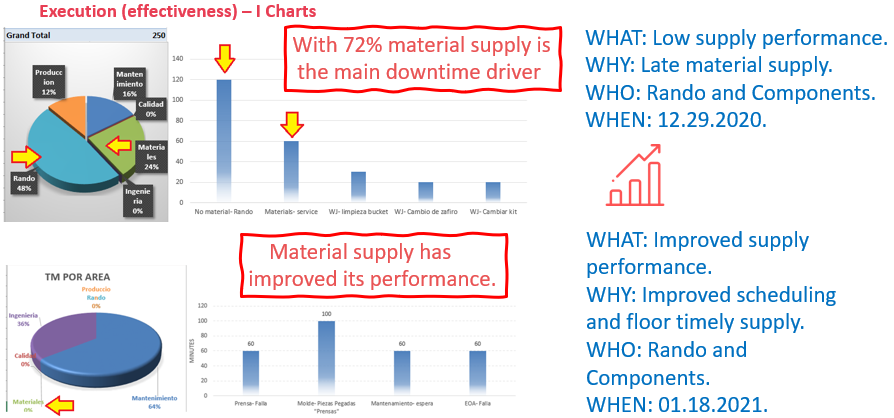

Company requested our support since they were having downtime in production work centers due to late supply inventory, lack of sense

of urgency, lack of coordination among different material teams and not very good scheduling in certain process.

We have been supporting our client by providing support in the following activities:

I. Determinate main drivers for late material delivery to work centers.

II. Change position expectations by increasing expectation on Leadership, accountability and communication.

III. ERP issues: Root-cause analysis for missing SAP label in WIP containers.

IV. Improving shipping process by taking out a rework area inside FG area. Avoid container mix.

V. Reduce automatic press shutdowns due to late material delivery by using kan ban concept or visual factory concept.

VI. Recognize achievements on material flow done by team member and raise expectations to middle management team.

AMBE helped to quickly identity and visualize the main issues, providing support by performing or coordinating the improvement of

these.

The Solution

The Result

Communication Sense of urgency

Before

After

Leadership Accountability

Before

After

Keep up Housekeeping

Before

After

Kan ban Implementation

Before

After