Mexican Border Automotive Suppliers

The Challenge

To identify Back logs orders by mapping each assigned supplier Logistics process and get the commitment of all parties involved in solving the issue by coordinating daily / weekly meetings in site and/or remote to obtain all information needed to anticipate risks to our Customer.

To keep our US OEM Customer informed of :

I. Back log orders by supplier and plants that might be in risk of interrupting their flow of vehicles.

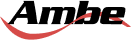

II. Offenders that created the backlog orders of each supplier

III. Supplier’s Action Plans to correct the offenders and avoid repeating

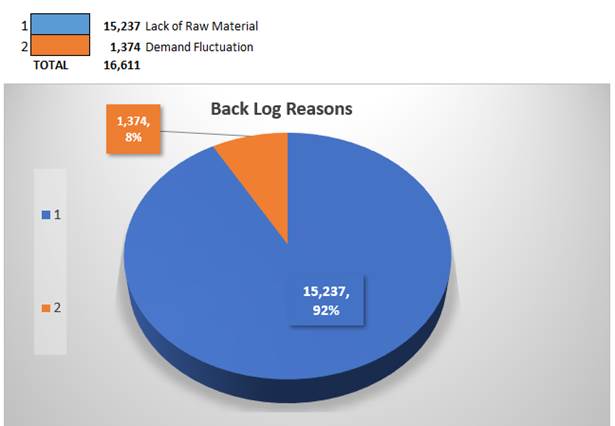

IV. Assurance of a backlog orders proper recovery plans in place and daily attainment to it

V. Assure sustainability: Measure results with KPI’s

Ambe help to coordinate proper teams in each supplier to obtain answers and commitments developing recovery plans with proper information that will assure the flow of vehicles in our customer plants.

The Solution

Mapping each supplier actual situation and Logistics processes to define and propose ways to anticipate risk to our Customer by:

• Identifying Actual Back log orders in each supplier plant.

• Identify coverage of Finished Goods in each Customer Plant.

• Understand reasons and offenders of each supplier situation.

• Implement and assure follow up of backlog recovery plans.

• To put in place KPI to proper follow of each supplier performance.

• Assure the follow up of actions plans when not hitting targets.

• Coordinate proper way of shipping product to assure arrival before customer plants identified coverage.

• Follow up of Raw Material Shortages that impact the attainment to each supplier recovery plan.

• Keep Customer informed on daily basis performance of each supplier.

The Result

Customer Visibility

Before

After

KPI’s

Before

After

Supplier Commitment

Before

After

Transparency

Before

After