Powertrain Automotive Customer

The Challenge

Root cause was the extra processes and activities for falling into a difficult financial situation for being cash in advance mode with all their supply chain.

To help our Customer to walk them thru a path that will direct them to reduce and/or eliminate:

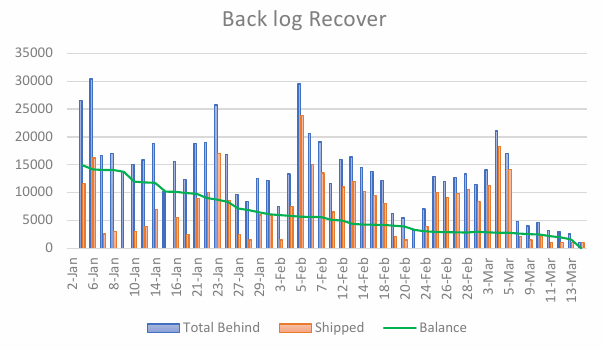

I. Back log orders: 60,000 over all back log when project initiated.

II. Shortage of components: + 30 components shortages

III. Premium freight: 4 -5 charters per day plus 3- 4 expedited trucks with no use of regular customer JIT trucks

IV. Identify quality concerns: Priority to get parts leaving quality aside

V. Assure sustainability: Measure results with KPI’s

Ambe help to eliminate mentioned issues and meet customer expectations regarding flow of information, way and frequency of their needs and teams

to be involved, at the same time to find a strategic way to manage customer pressure to obtain desired results within short period of time

The Solution

Map and understand the manufacturer actual processes and extra systems created due their cash in advance situation and develop a plan that will

allow agile flow of information by identifying and assuring a way to follow and control following tasks

- Analyze Preform process analysis. (Cash in advance System)

- Understand Back log actual situation.

- Assure Data and reports collect.

- Steps for Demand Processing.

- Creation of Production Plan.

- Review Customer Plants coverage.

- Implement Back log recovery plan.

- Follow up Raw Material shortages.

- Identify Deviation of regular processes.

The Result

Transportation

Before

After

System & Training

Before

After

Back log and shortage of components

Before

After

Costs

Before

After